ISOBUS SLURRY-Controller serves as a control and regulating device for slurry tankers. In addition to forward speed-independent regulation, the system also offers a multitude of specific functions.

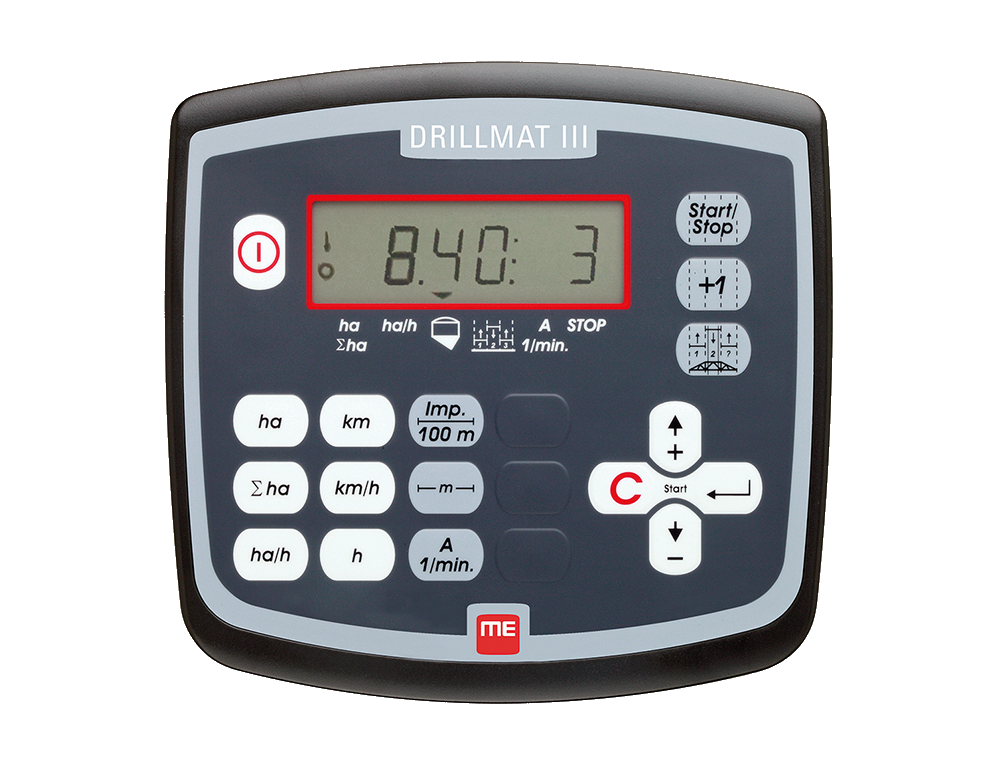

All of the relevant information for the driver is visible at a glance on the work screen, and the filling and application areas can be selected. Especially when changing from field to road, this facilitates the operation and prevents operating errors.

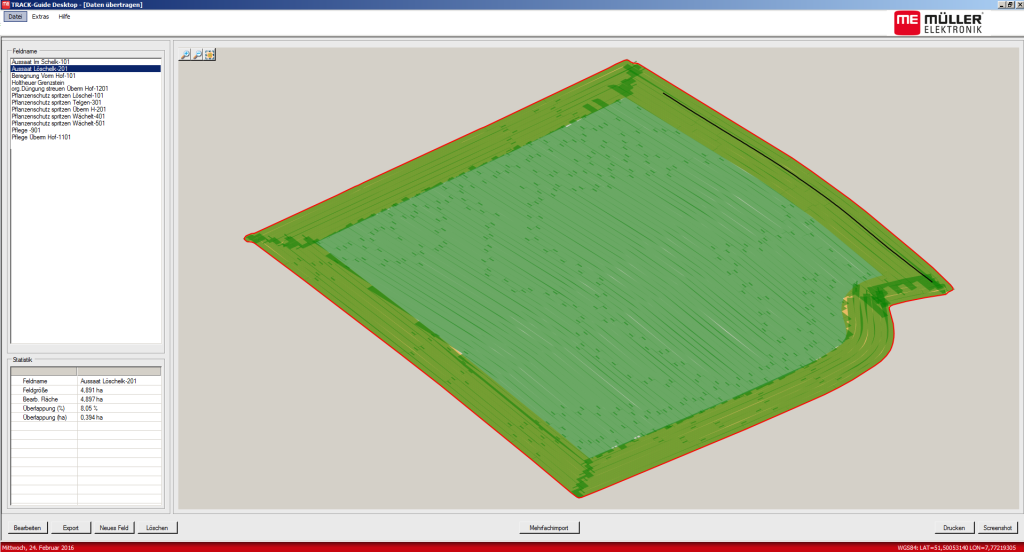

The system can be individually adapted – whether it be for a simple slurry tanker or a complex solution. The great flexibility of the hardware and software guarantee a compatible, stable and state-of-the-art system on the long term. The ISOBUS TASK-Controller ensures perfect documentation via ISO-XML.