Calibrate the nozzles

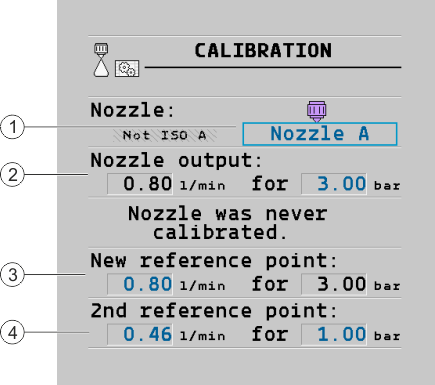

Illustration

Procedure

Calibrate a standard nozzle as follows:

- þ

- The tank is filled with clear water.

- þ

- There are no spray liquid residues in the tank or the pipelines.

- 4.

- Using a measuring cup, collect the water from several nozzles for one minute each.

- 5.

- Calculate average application rate.

- 9.

- On the "Nozzle" line – select nozzle for calibration. Standard nozzles are referred to by their colours.

- 10.

- In the box below the "New reference point" line, enter the calculated average quantity in l/min.

- 11.

- For undefined nozzles, you must also enter the nozzle's minimum output in the "2nd reference point" parameter. To do so, you must repeat the procedure at a different pressure.

- ⇨

- You have calibrated the selected nozzle.

- On the work screen, switch the application mode to manual.

- On the work screen, switch the application mode to manual. - Start application.

- Start application. and

and  - Set the spray pressure to 3 bar.

- Set the spray pressure to 3 bar. >

>  >

>