Standard products:

Application Seeding

ISOBUS PLANTER-Controller

Control system for precision planters

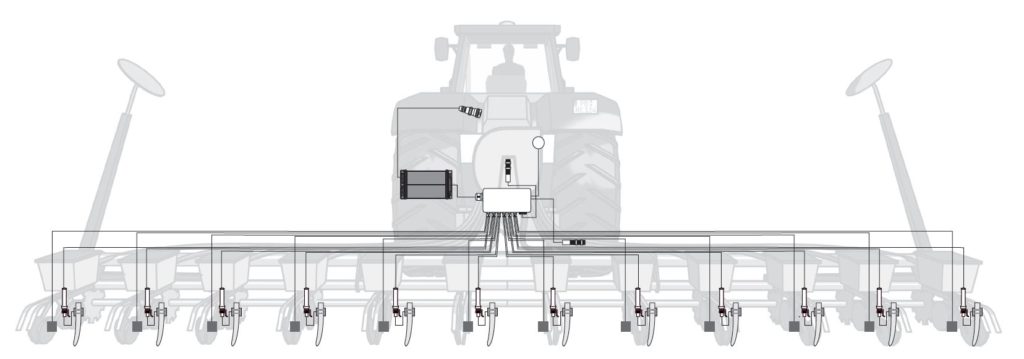

The ISOBUS PLANTER-Controller is a control system for implements with mechanical, central or single drive. It supports up to 24 rows with SECTION-Control.

The job computer regulates the application rate according to the set target rate in seeds per hectare. Hydraulic motors and sometimes also electric motors can be used to achieve regulation.

In addition, different shut-off clutches can be switched manually or automatically (SECTION-Control) for each metering unit.

The motor control of the application rate per row allows the optimum seed placement and holds a great savings potential.

The graphic representation of the placement statistics enables comprehensive diagnostic of the seed placement. The singulation, gaps and doubles, seed spacing, and seed rate per area must be considered.

Product advantages:

- Individual seed rates per row

- Extensive placement statistics for each row with 60-second history

- Easy configuration via UT

- Intuitive touch operation

Images & Videos

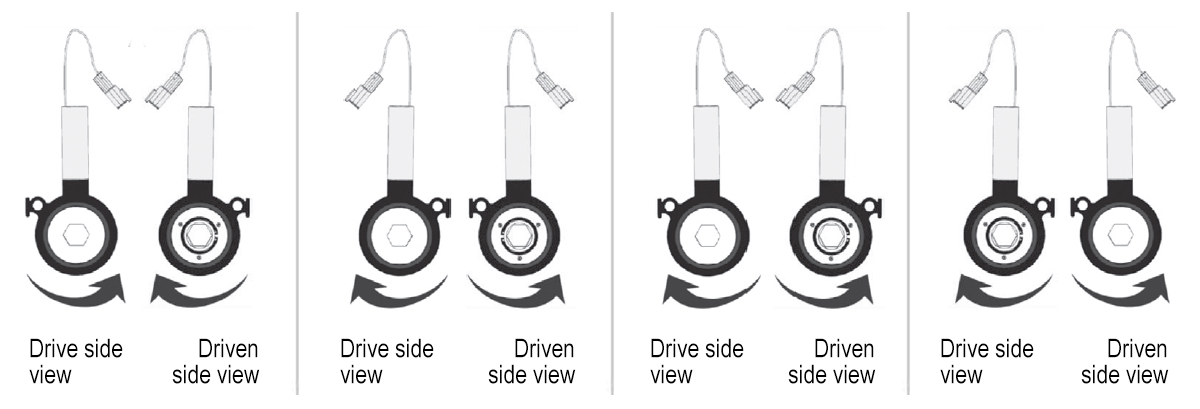

Shut-off clutches

Shut-off clutches

The electric shut-off clutch can be used for switching individual seeding units when working with precision planters. Up to 12 shut-off clutches per ECU can be supported. The high number of maximum 24 latching possibilities increases the accuracy of the seed placement when switching off.

The housing and seal design prevent contaminants from entering the shut-off clutch.

Blockage Monitoring

Used as a pure blockage monitoring system, the PLANTER-Controller supports up to 32 rows with SECTION-Control when using two ECUs.