Hoeing machines equipped with ME technology work with all ISOBUS terminals on the market and can therefore be integrated in the existing mechanisation of the farms without any problems.

On the headlands, the crop plants in the transverse rows are protected thanks to automatic lowering and raising with SECTION-Control. To secure yields, the optimal number of crop plants per hectare is maintained.

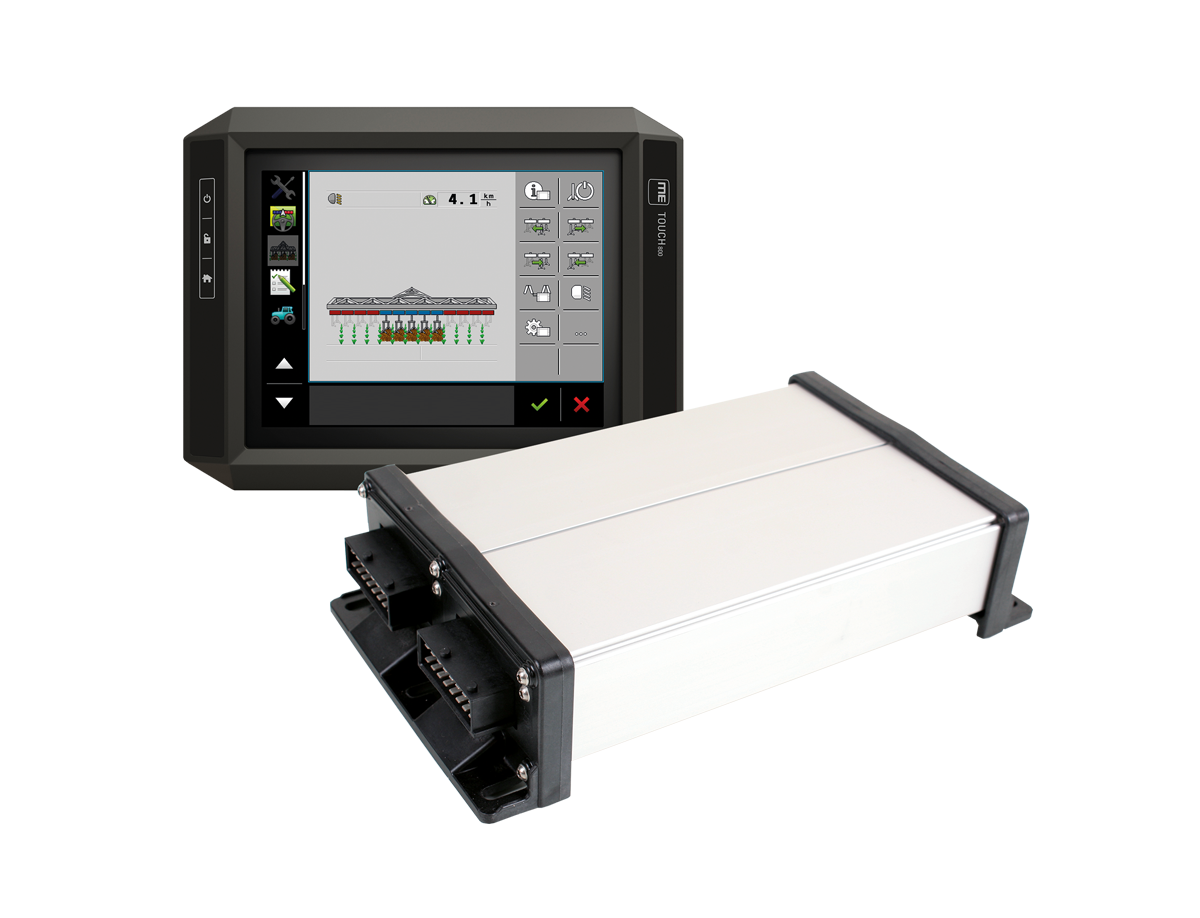

Large implements with more than 3 m working width require hydraulic transport folding, which is also controlled by the MIDI 3.0 job computer. In combination with another MIDI job computer and the sprayer software, combination implements with a so-called band sprayer can also be realised.

Because band spraying only treats the actual plant row and no double treatment is possible in conjunction with SECTION-Control, this achieves the highest degree of environmental and consumer protection.