Blockage measures the flow in all agricultural implements where individual particles are conveyed with air or by free-fall.

The sensor is primarily used to monitor the flow of fertilizer in precision planters as well as to monitor seeding in pneumatic seeders. Thanks to the modular design Blockage can be adapted to any hose diameter, enabling other application options.

The blockage sensor detects all common materials – ranging from large seeds like maize, soya and fertilizers via all sorts of cereals through to fine seeds and micropellets.

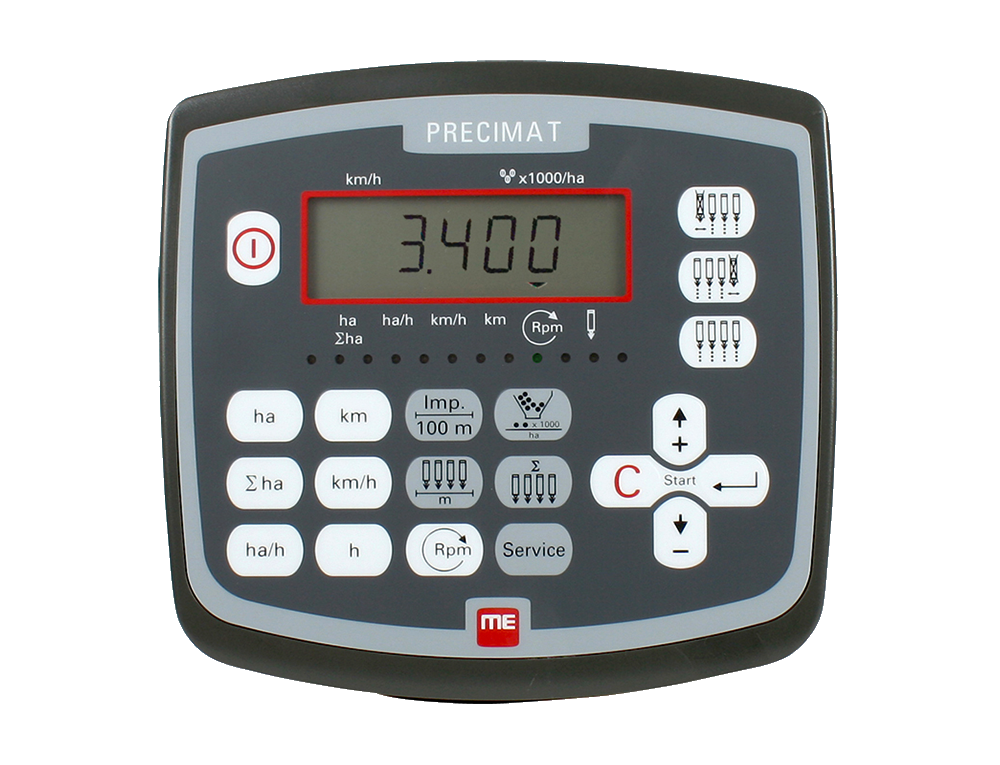

The system can be used in different ways. It is either integrated in the existing seeder and thus communicates with the job computer or the system operates independently and is directly integrated on the ISOBUS as an implement. A stand-alone version, consisting only of implement monitoring, is also possible.