DRILLMAT III is used on seeders to automatically create tramlines. The variety of different pre-programmed rhythms allows for the combination of any seeder working width with the desired tramline spacing.

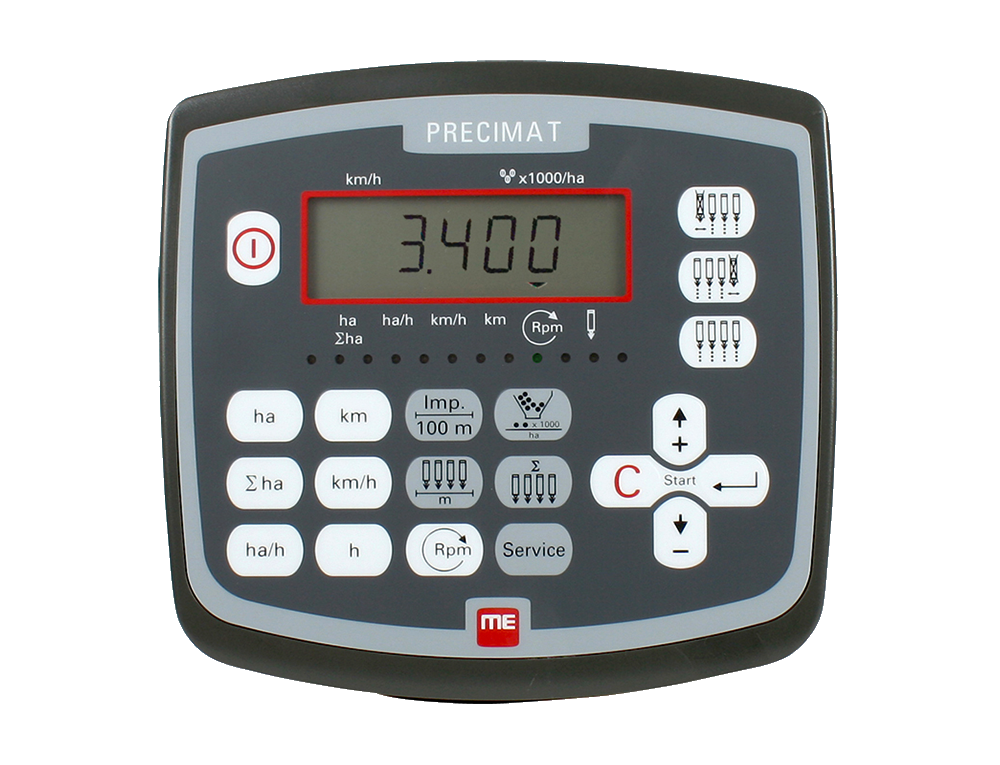

Seeding can begin both on the right and the left side of the field. Manual switching is also possible. The DRILLMAT III is also used to monitor the seeder. The metering shaft and fan speeds are continuously monitored. A fill level sensor indicates low seed levels. In addition, the DRILLMAT III provides information on seeded areas, area output, covered distance and speed.