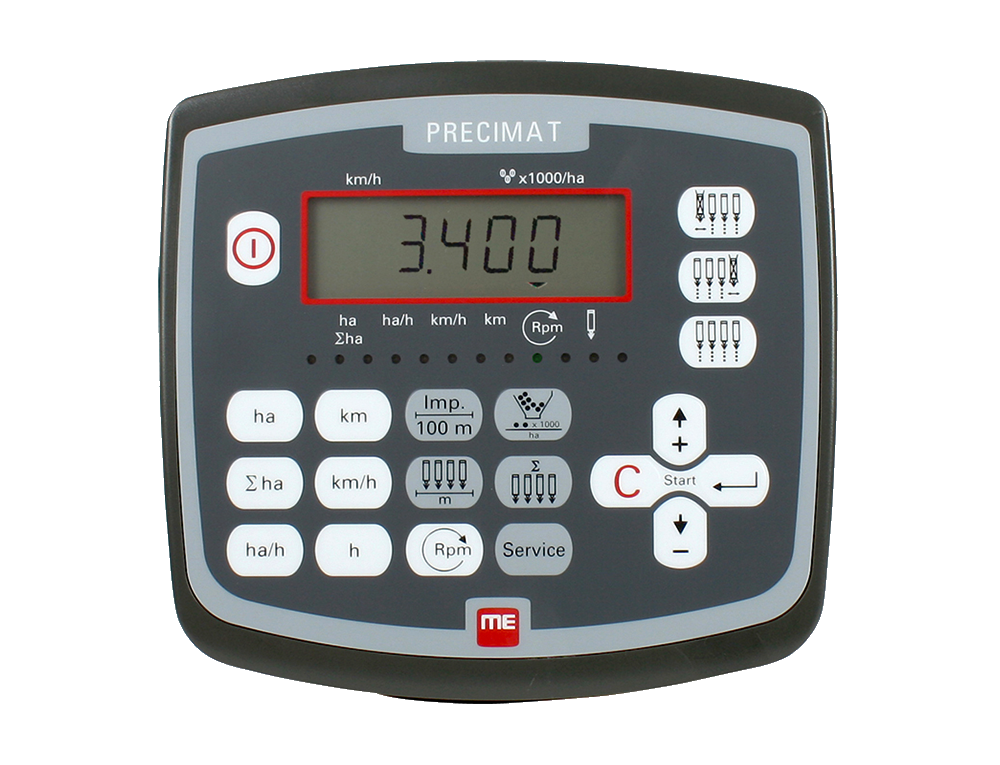

PRECIMAT is a monitoring device for precision planters with seed counting.

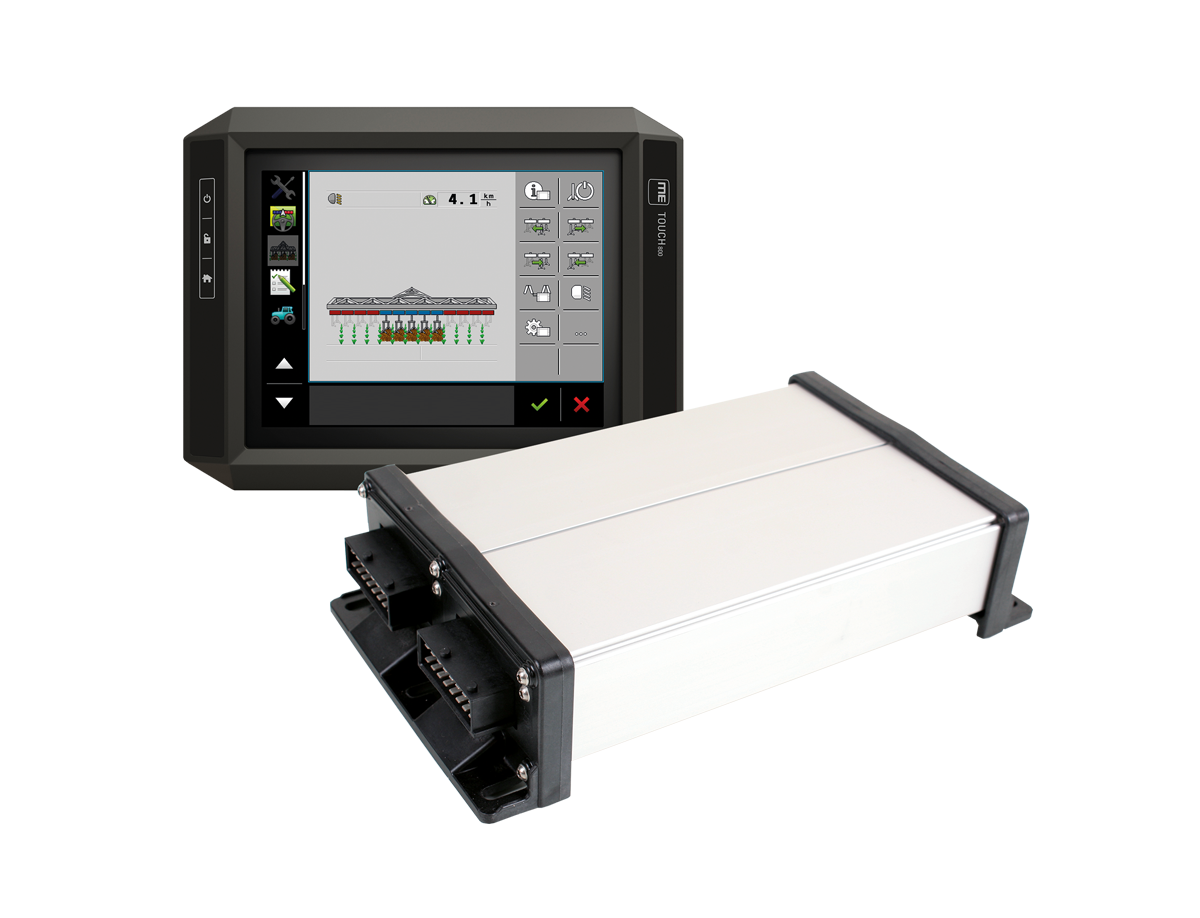

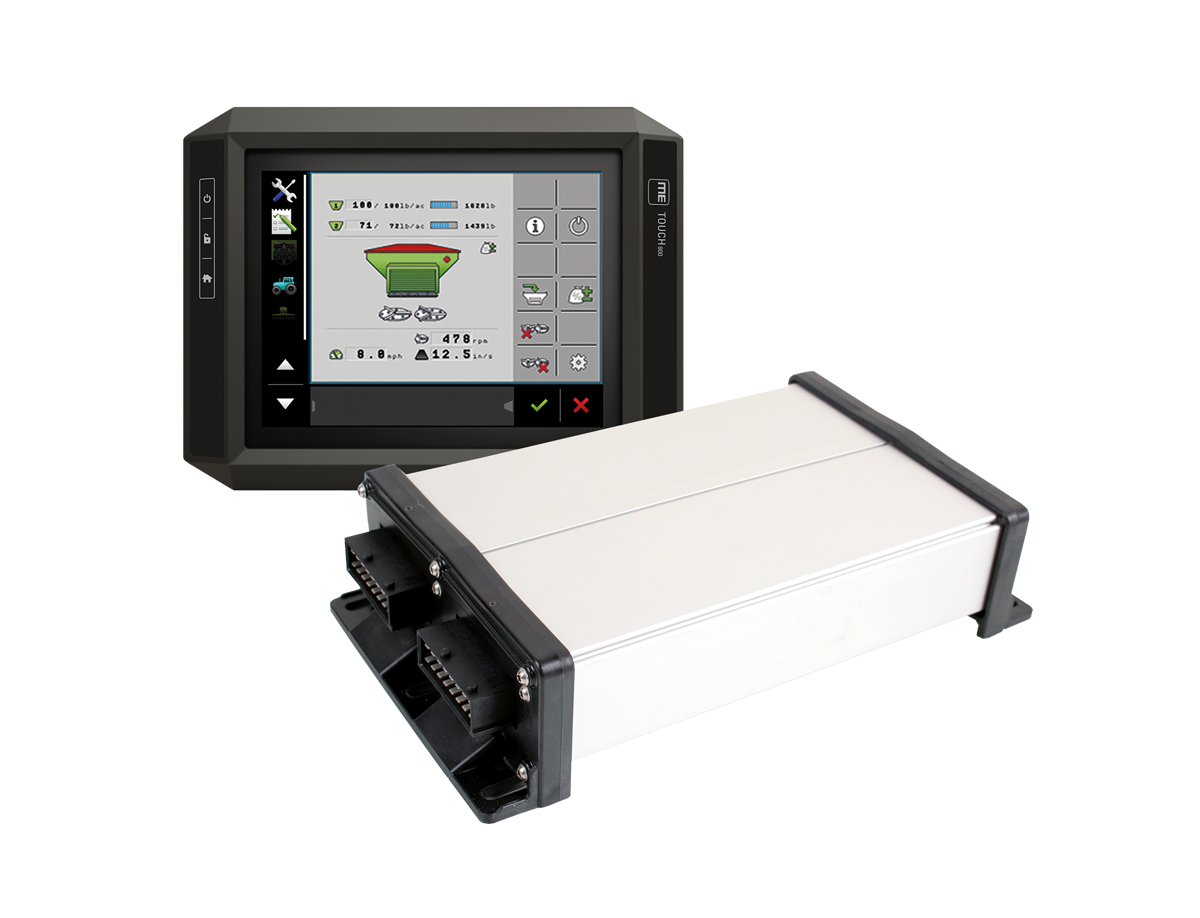

Up to 12 seeding units can be monitored with optical sensors. It is also possible to shut off up to 12 seeding units. Alternatively, on implements with more than 12 rows, it is also possible not to use any monitoring and therefore shut off up to 18 seeding units.

In addition to precision planting, the PRECIMAT can also be used as a hectare counter for all other applications.